2 (L) Schematic of an ejector; (R) Parameters of an ejector in calculation 4. Experimental set up 4.1. Experimental testing device For a purpose of measuring the actual performance of an ejector cycle, an indoor testing device was set up. Figure 3 shows a schematic of the whole set of testing device, which consists of a vapor generator. Therefore ejector curves at fixed ejector geometry are calculated at the design discharge pressure and an increased discharge pressure (see 3.2). These are more indicative of the response of a specific ejector to changes in inputs. An ejector is a device used to suck the gas or vapour from the desired vessel or system. An ejector is similar to a vacuum pump or compressor. The major difference between the ejector and vacuum pump or compressor is it had no moving parts. Hence it is relatively low-cost and easy to operate and maintenance-free equipment. Ejector Working Principle. The ejector design principles used in the ejector calculations for the program are explained including the ejector energy balance and effects of the ejector flow cones. Free demo programs for a short time are offered to let you see how the ejector program works - they are not intended for your design work. The actual ejector designs can also be. Mar 23, 2012 - ejectors, which were specifically designed for the process rather than. The calculation of Pr3 will then enable the dimensions of the mixing. A Transvac Ejector (venturi, eductor, jet pump) operation is based upon Bernoulli’s Principle which states: ‘When the speed of a fluid increases its pressure decreases and vice versa’.

In this article, we will see the Ejector Working Principle

What is Ejector?

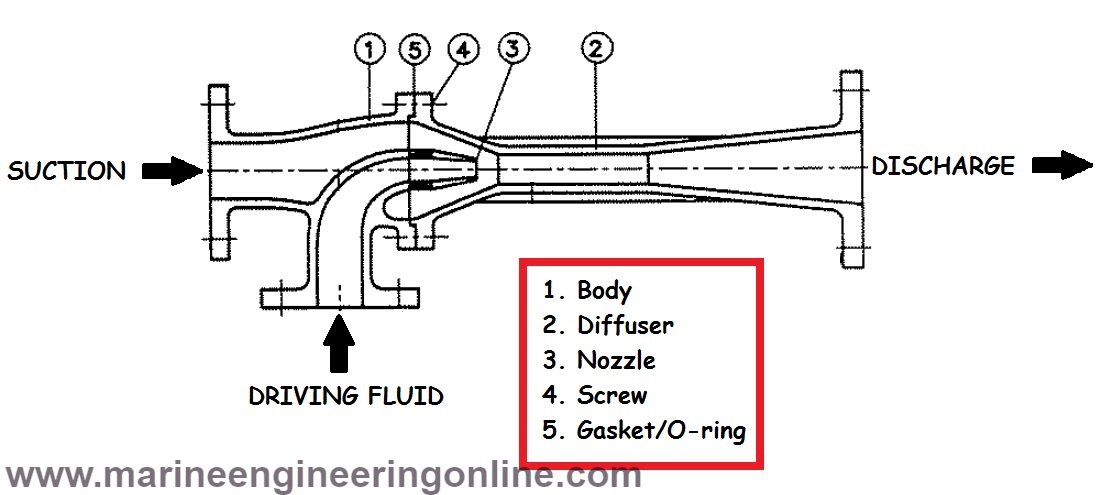

An ejector is a device used to suck the gas or vapour from the desired vessel or system. An ejector is similar to a vacuum pump or compressor. The major difference between the ejector and vacuum pump or compressor is it had no moving parts. Hence it is relatively low-cost and easy to operate and maintenance-free equipment.

Ejector Working Principle

The operating principle of the ejector is the pressure energy in the motive fluid is converted to velocity energy by an adiabatic expansion in the Converging/Diverging

The operating principle of the ejector is the pressure energy in the motive fluid is converted to velocity energy by an adiabatic expansion in the Converging/Diverging Nozzle. Due to the pressure drop of the motive fluid, it will create a low-pressure zone before the mixing chamber. Due to the low-pressure zone, the suction fluid will start to move toward it and mix with motive fluid in the mixing chamber. In mixed fluid enter the diverging portion of the ejector where its velocity energy is converted into pressure energy.

Working of Ejector

The suction line of the ejector is connected to the vessel which is to the kept under low pressure. Refer to the below figure, a high pressure motivating fluid enters at “A” and expands through the converging-diverging nozzle to “B”. The motive fluid will create a vacuum in the mixing chamber refer to to the pressure curve where the pressure is decreased and velocity is increased. Due to this suction fluid “C” (air or gas) from the connected vessel moves toward the mixing chamber “D”. When the suction fluid starts to mix with the motive fluid in the mixing chamber. The velocity of the fluid at the mixing chamber is approximately 600 to 900 meters per second.

Then the mixture travels through the diffuser “E”, its velocity energy is converted into pressure energy. Thereby the mixture gained higher pressure send to the atmosphere or some closed system. Normally the discharge pressure will be 10 to 15 times of the suction pressure

Air Ejector Design Calculations

Capacity of Ejectors

The capacity of an ejector is determined by its dimensions. By the required capacity is very high then two or three ejectors are working in parallel. if greater compression is required, two or more ejectors will be arranged in series.

Ejector Installation

Ejectors may be installed at any orientation. However, it is very important to provide a provision to remove the condensate or solid particles from the entrained gases of an ejector. Since any condensed or solid particles may reduce the throughput capacity of the ejectors.

Hence it very important to provide a drain valve installed at low points can be either manual or automatic float operated valves.

Another important thing to check during ejector installation is external loads(Piping load) act on the ejectors. Since any misalignment will adversely affect the performance of ejector.

Ejector Benefits

- Ejectors can be operated with many different motive fluids: steam, air, organic vapour and other gases.

- No moving parts, no lubrication, no vibration. Hence low maintenance cost when compared with other peer equipment.

- Ejectors can be installed indoors or outdoors without restriction.

- Can be installed at any orientation. Hence space requirement will be very low.

- The initial cost is very less and no spares required.

- Easy to handle corrosive and slugging liquids.

In this article, we will see the Ejector Working Principle

What is Ejector?

An ejector is a device used to suck the gas or vapour from the desired vessel or system. An ejector is similar to a vacuum pump or compressor. The major difference between the ejector and vacuum pump or compressor is it had no moving parts. Hence it is relatively low-cost and easy to operate and maintenance-free equipment.

Ejector Working Principle

Ejector Design Calculation Pdf

The operating principle of the ejector is the pressure energy in the motive fluid is converted to velocity energy by an adiabatic expansion in the Converging/Diverging

The operating principle of the ejector is the pressure energy in the motive fluid is converted to velocity energy by an adiabatic expansion in the Converging/Diverging Nozzle. Due to the pressure drop of the motive fluid, it will create a low-pressure zone before the mixing chamber. Due to the low-pressure zone, the suction fluid will start to move toward it and mix with motive fluid in the mixing chamber. In mixed fluid enter the diverging portion of the ejector where its velocity energy is converted into pressure energy.

Working of Ejector

The suction line of the ejector is connected to the vessel which is to the kept under low pressure. Refer to the below figure, a high pressure motivating fluid enters at “A” and expands through the converging-diverging nozzle to “B”. The motive fluid will create a vacuum in the mixing chamber refer to to the pressure curve where the pressure is decreased and velocity is increased. Due to this suction fluid “C” (air or gas) from the connected vessel moves toward the mixing chamber “D”. When the suction fluid starts to mix with the motive fluid in the mixing chamber. The velocity of the fluid at the mixing chamber is approximately 600 to 900 meters per second.

Then the mixture travels through the diffuser “E”, its velocity energy is converted into pressure energy. Thereby the mixture gained higher pressure send to the atmosphere or some closed system. Normally the discharge pressure will be 10 to 15 times of the suction pressure

Capacity of Ejectors

The capacity of an ejector is determined by its dimensions. By the required capacity is very high then two or three ejectors are working in parallel. if greater compression is required, two or more ejectors will be arranged in series.

Ejector Installation

Ejectors may be installed at any orientation. However, it is very important to provide a provision to remove the condensate or solid particles from the entrained gases of an ejector. Since any condensed or solid particles may reduce the throughput capacity of the ejectors.

Hence it very important to provide a drain valve installed at low points can be either manual or automatic float operated valves.

Another important thing to check during ejector installation is external loads(Piping load) act on the ejectors. Since any misalignment will adversely affect the performance of ejector.

Ejector Benefits

Ejector Design Calculation

- Ejectors can be operated with many different motive fluids: steam, air, organic vapour and other gases.

- No moving parts, no lubrication, no vibration. Hence low maintenance cost when compared with other peer equipment.

- Ejectors can be installed indoors or outdoors without restriction.

- Can be installed at any orientation. Hence space requirement will be very low.

- The initial cost is very less and no spares required.

- Easy to handle corrosive and slugging liquids.